KL group is committed to producing more reliable and hygienic products, so as to promote the progress of environment, science technology and health.

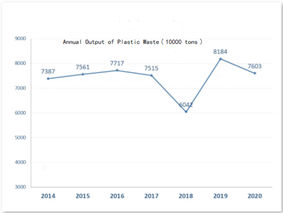

Since 2020, after the government issued 《Opinions on Further Strengthening The Treatment of Plastic Pollution》, the annual output of plastic waste in that year was lower than that in 2019, but higher than the historical average.

In 2021, the upgraded "Plastic Restriction" was implemented everywhere in China, which reflected the severe situation caused by domestic plastic waste.

Practice& Action

As a leading enterprise in the domestic sanitary materials industry, KL group has spared no effort to promote food safety and environmental protection.

Over the years, KingLai has focused on improving domestic food safety standards, insisted on promoting the construction of hygienic production environment in the food industry, so as to keep steps with international standards.

In recent years, it is glad to find that the dairy brand has actively responded to Kigali’s call - "produce food with medical &health standards", and all dairy factories have gradually moved closer to medical standards!

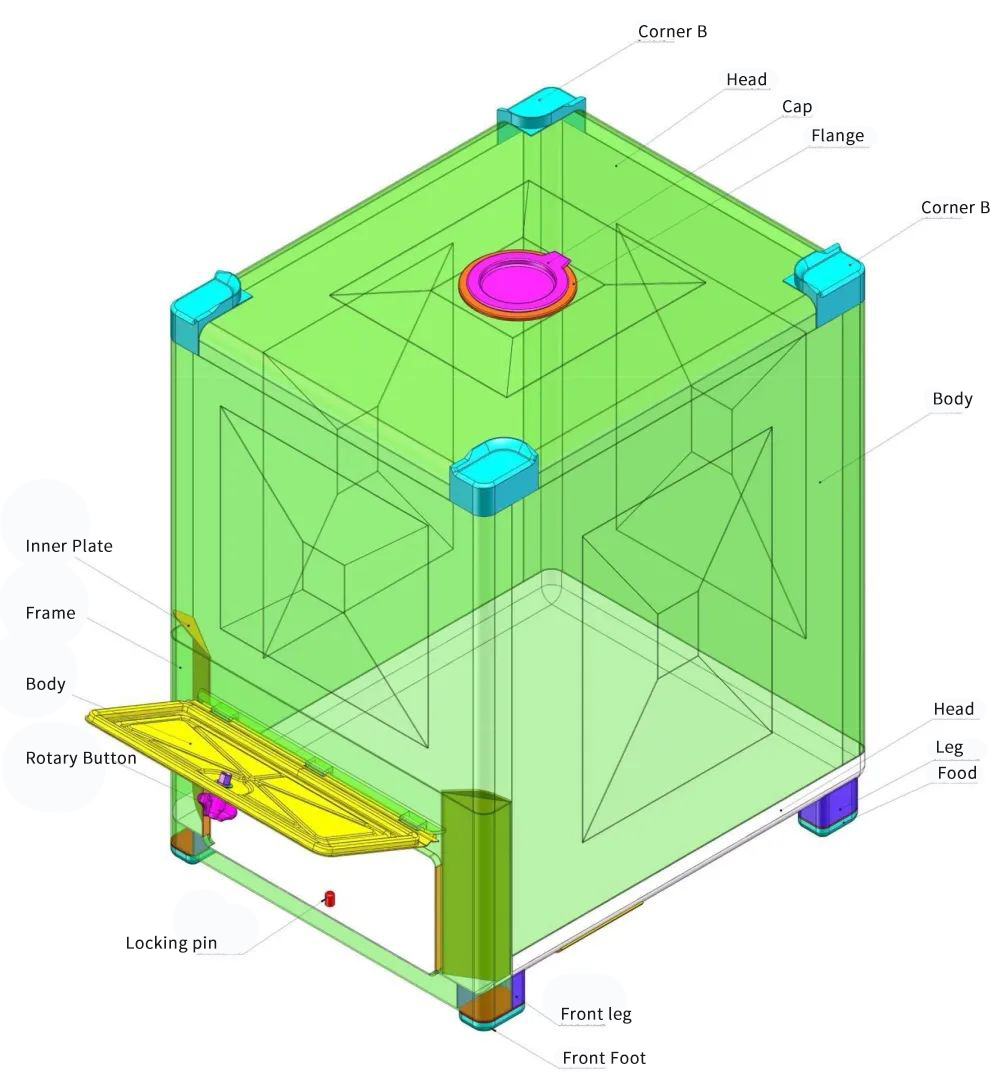

In view of the excessive use of plastics in the storage process, KingLai has developed a new residue free & hygienic powder box, to ensure the safety and environmental protection for the storage process before canning of milk powder.

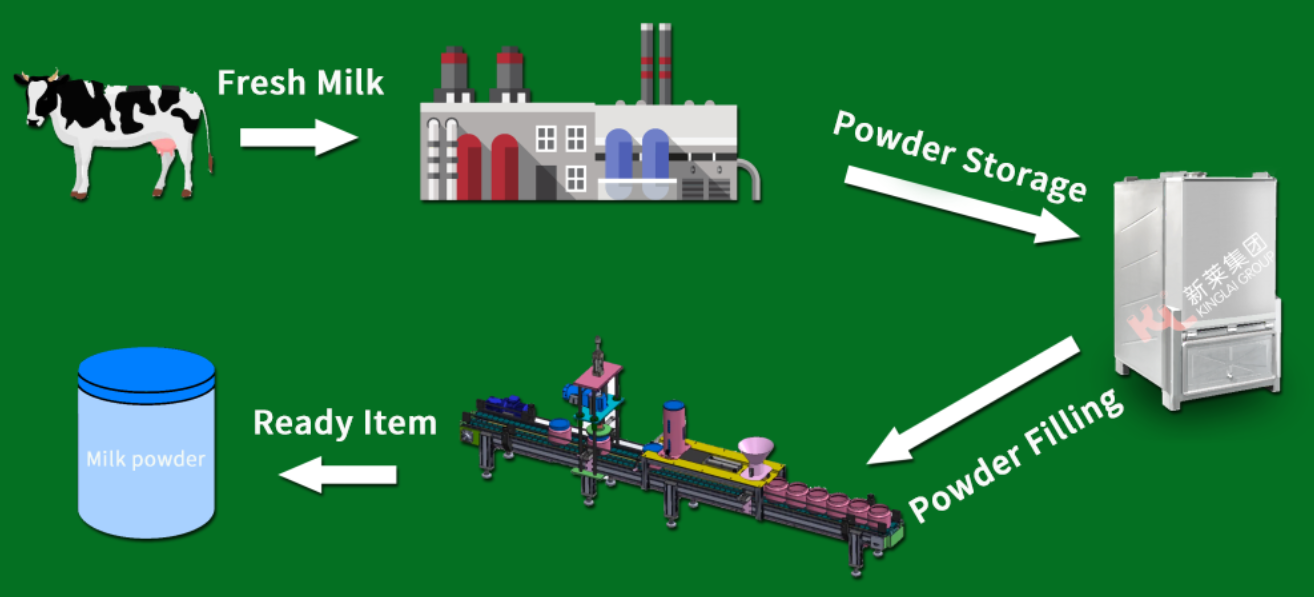

Milk Powder Production Process

2022.12.01 KL Group·New Powder Box Design

Introduction: the safety of milk powder is related to the healthy growth of every kid. Therefore, every process in the milk powder production needs to be controlled strictly.

Question: Why does KL develop new powder boxes?

Answer: In order to promote the progress of food safety and environmental protection, as well as reduce the generation of plastic waste, and help China achieve its carbon emission target, KL develops the new powder box.

At present, the commonly used storage container of raw powder - flexible container bag (ton bag) is composed of outer ton bag and inner membrane bag.

01.Outer Ton Bag

It is generally made of polyester fibers such as polypropylene and polyethylene. The outer ton bag can be used for load-bearing and transportation, and it can be reused.

02.Inner Membrane Bag

It is usually made of polyethylene blown film. The inner bag can be used for packaging, moisture-proof and sealing, and it can not be reused.

The ton bag has the advantages of simple structure, light weight, foldable, small space occupied and low price, and has been widely praised. But there are also many defects:

1. Personnel safety hazards

After the worn of the four slings, the risk of bag dropping increases.

2. Inconvenient operation

The flexible characteristics and hoisting method of ton bag make it inconvenient for filling or leaning, which causes residues.

3. Food safety hazards

The ton bag is made of fiber textile, which is easy to be polluted. Therefore, extra attention should be paid to all aspects during usage (such as preventing the ton bag from being punctured by forklift, and prevent the ton bag from directly putting on the ground, etc.)

4. High environmental pollution

As a temporary storage container, the service life of ton bags is 2-3 days, after that the inner membrane bags need to be replaced immediately. The discarded inner membrane bags are not degradable and will be recycled as plastic waste. The treatment or landfill of the plastic waste will cause damage to the environment.

Question: What are the advantages of KL powder box?

Answers:

1. No plastic waste and less plastic pollution.

2. Long service life and cost saving.

3. High structure strength and good sealing performance.

4. There is no residue in the box and the inter space is easy to clean.

5. More convenient storage and operation.

Question: What are the KingLai powder box features?

Answers:

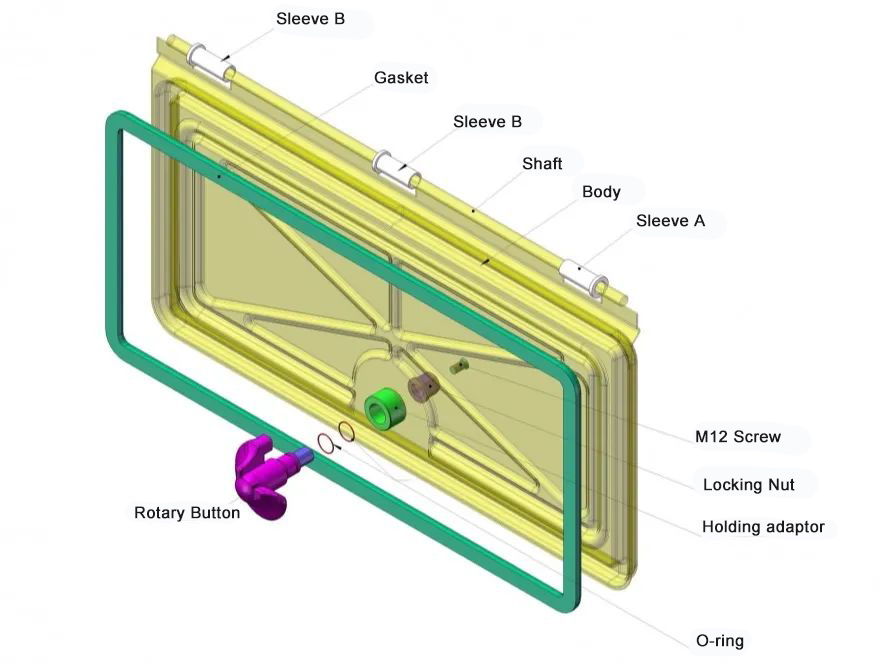

01. The inner wall is with large corner or arc design, the corner is larger than or equal to 120 degrees, and the inner surface is mirror polished to reduce the residue of powder.

02. The powder outlet is with food grade silicon sealing structure, which will not catch any powder. In addition, the powder box is inspected by higher level of leaking test standard to detect the sealing of the powder box. Fully filling the box with water, and then dropping the box to the ground, finally the box does not leak, the door does not deform, and the door can be opened and closed freely.

03. The design of conical powder box is scientific and the weight control is optimized, so it is convenient to move under various working conditions. Funnel structure & mirror polishing is conducive to the natural powder production under the influence of gravity.

04. The powder box adopts stamping stiffener design, which has better strength and beautiful appearance.

The powder box is made of 304 stainless steel plate, and there is a strengthening plate in the box.

At the same time, KingLai also strives for perfection in the details:

Powder box details

1. The support seats holes of three box doors are concentric to ensure that the door and frame can be opened flexibly after assembly, and the loading and unloading is smooth without any jamming.

2. The sealing gasket is made of food grade silicon, which will not fall off automatically when the door is open.

3. All parts in contact with operators shall not have sharp edges.

Supportive R&D Background

Since the establishment of the enterprise, KingLai has established the R &D department. After 20 years of exploration and precipitation, it has accumulated rich design experience in many fields, such as dairy filling machine, CIP machine, UHT ultra-high temperature instantaneous sterilization, heat exchanger, pump, valve, pressure vessels, tubes and fittings. Through self-developed equipment, KingLai has put advanced design theory to support production capacity.

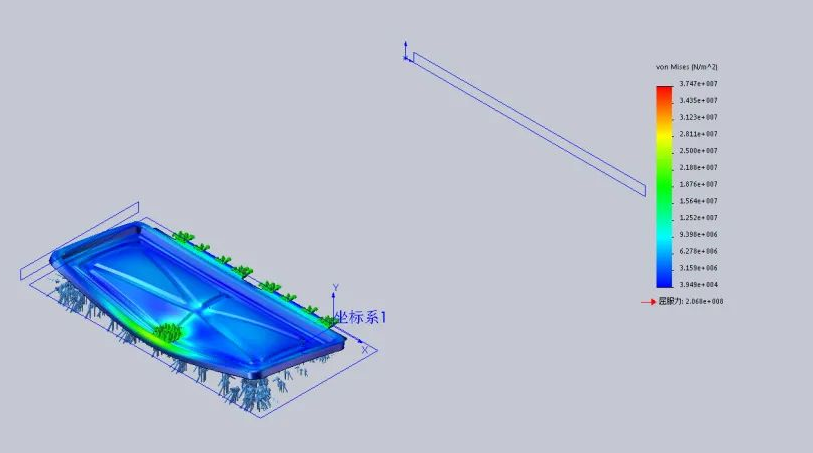

In order to meet the design requirements of food safety and environmental protection, the R & D department demonstrated several schemes through FEM (Finite Element Method) and found the best design.

Finite Element Method

KingLai group sticks to its mission and makes every effort for the cause of environmental protection in China and the world!

免责声明:文章仅供学习和交流,如涉及作品版权问题需要我方删除,请联系我们,我们会在第一时间进行处理。